Views: 0 Author: Site Editor Publish Time: 2025-08-26 Origin: Site

If you want to measure v-belts for replacement, follow some steps. First, look at your v belt type. Next, write down the width and depth. Then, measure or figure out the length. These facts help you get the right v-belt part number. Measuring right is important for DIY users and professionals. Here are some common problems:

Challenge | DIY Users | Professionals |

|---|---|---|

Correct Sizing | Sometimes hard | Use manufacturer specs |

Proper Tension | Tough without right tools | Use tension gauges |

System Complexity | Simple systems only | Work with complex setups |

If your system is hard to measure, Uliflex’s experts can help you.

Find out your v-belt type by looking at the part number. You can also measure the belt’s width and depth. This helps you pick the right replacement.

Use a soft cloth tape or a bendy measuring tool. Measure the belt’s width, depth, and outside length. Do not use hard steel tapes because they are not accurate.

If you do not have the old belt, measure the pulley diameters and the center distance. You can also use a string to figure out the right belt length.

Use math or look at manufacturer charts to find the closest standard belt length. Match this with the correct part number before you order.

Do not make mistakes like loose measurements or using the wrong tools. Do not forget to check for pulley wear. Ask an expert if you are not sure. This can save you time and money.

When you look at a v belt, you might notice that not all belts look the same. Each v-belt has a specific shape and size, called its profile. You can identify the belt type and profile by checking the part number printed on the belt. Sometimes, this number wears off, so you may need to measure the belt’s top width and thickness. For example, a belt marked "5V500" means it has a 5/8-inch top width and is 50 inches long. Fractional horsepower belts use codes like 3L or 4L, which also tell you the width and length.

Here’s a quick way to identify common v-belt profiles:

Look for the part number on the belt.

Measure the top width and thickness if the number is missing.

Compare your measurements to standard sizes.

Check if the belt is wrapped, cogged, or banded.

Write down the length by wrapping a string around the belt or pulleys.

You can also use this table to see the most common v-belt types and where you might find them:

V-Belt Type | Description | Common Applications |

|---|---|---|

Classical V-belt | Oldest and most common; sizes A to E. | Agriculture, ventilation, machinery |

Narrow V series | Deeper and more efficient; sizes 3V, 5V, 8V. | High-power drives, compact spaces |

Fractional Horsepower (FHP) | Light-duty; sizes 2L, 3L, 4L, 5L. | Small appliances, fans, home equipment |

Choosing the right v-belt type makes a big difference for your machine. If you pick the correct belt, your system runs smoothly and lasts longer. The right v belt helps prevent slippage, which means less heat and less wear on your pulleys. You also get better power transfer, so your machine works more efficiently.

If you use the wrong belt, you might notice more noise, vibration, or even damage to your equipment. Some v-belts, like cogged or banded types, work better in tough conditions or with sudden direction changes. Others, like narrow v-belts, handle more power in a smaller space. Always match the belt type and profile to your machine’s needs. This simple step saves you time, money, and trouble down the road.

Tip: If you’re not sure which v-belt fits your machine, Uliflex’s technical team can help you find the perfect match.

You want to measure v belts the right way, so you need the right tools. Using the wrong tool can give you the wrong size, which means your machine might not work as it should. Here’s a quick look at what you need:

Measurement Aspect | Recommended Tools | Reason/Notes |

|---|---|---|

Width | Straight ruler or fabric tape measure | Fabric tape measure bends with the belt’s curve |

Depth | Fabric tape measure | Keeps measurement accurate, avoids skewed results |

Length (Circumference) | Fabric tape measure, straight-edge ruler, or metal ruler | Fabric tape measure is flexible and precise |

A soft measuring tape or fabric tape measure works best for measuring belts. You can also use a v belt measuring tool for extra accuracy. If you don’t have a belt, a nylon rope can help you measure around the pulleys. Mark the rope, lay it flat, and measure the distance between marks. This gives you the belt length you need.

Tip: Avoid steel tape measures. They are stiff and can’t wrap around the belt or pulleys. Cloth tape or string fits snugly and gives you a better measurement.

Getting the width and depth right is key for finding the correct replacement. You want to measure the top width and the thickness (depth) of the v-belt. Use a ruler or a caliper for the width. Place the tool across the top of the belt, not the side. For depth, measure from the top to the bottom of the belt’s cross-section.

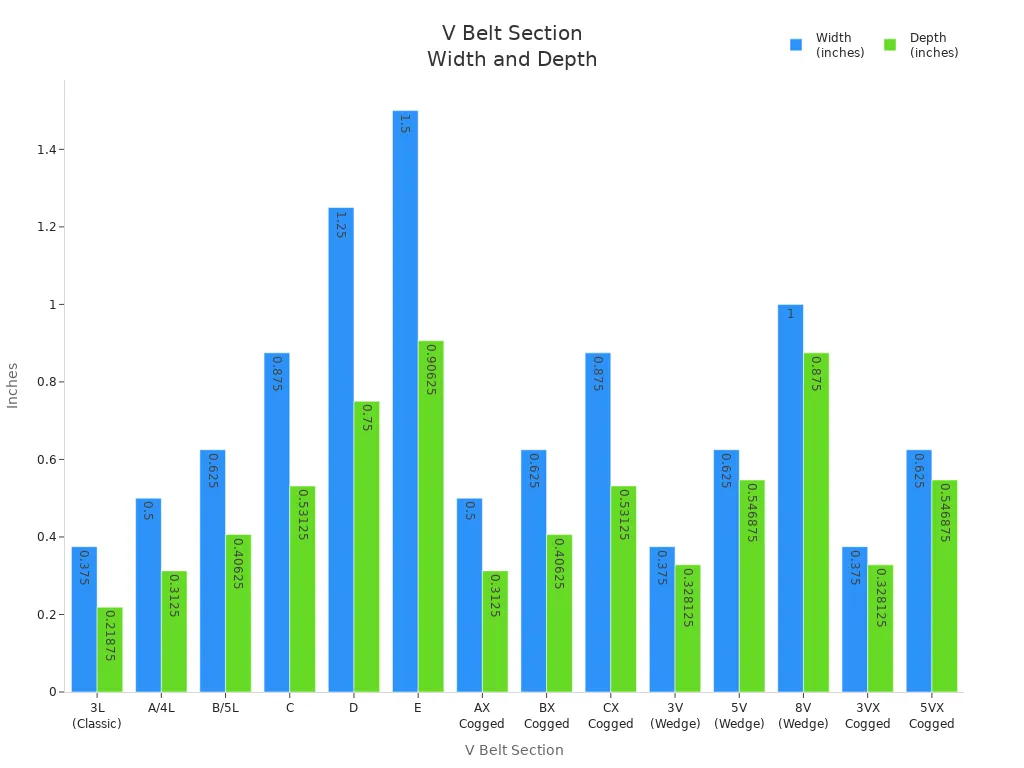

Here’s a table to help you match your measurements to common v belt types:

V Belt Section | Width (inches) | Depth (inches) |

|---|---|---|

3L (Classic) | 3/8 | 7/32 |

A/4L | 1/2 | 5/16 |

B/5L | 5/8 | 13/32 |

C | 7/8 | 17/32 |

D | 1-1/4 | 3/4 |

E | 1-1/2 | 29/32 |

AX Cogged | 1/2 | 5/16 |

BX Cogged | 5/8 | 13/32 |

CX Cogged | 7/8 | 17/32 |

3V (Wedge) | 3/8 | 21/64 |

5V (Wedge) | 5/8 | 35/64 |

8V (Wedge) | 1 | 7/8 |

3VX Cogged | 3/8 | 21/64 |

5VX Cogged | 5/8 | 35/64 |

When you record these numbers, write down the width and depth first. This helps you match the belt to the right part number. If you use a v-belt measuring tool, you can double-check your results.

Note: Always measure the belt when it’s off the machine. If you measure while it’s installed, you might get the wrong size because of tension or wear.

The outside belt length tells you how long the belt needs to be to fit your machine. You want to measure the outside circumference, not the diameter. Wrap a cloth tape or string around the outside of the belt. Pull it snug, but don’t stretch it too much. Mark where the tape meets itself, then lay it flat and measure the distance between marks.

Here’s why cloth tape or string works better than steel tape:

Cloth tape or string wraps tightly and follows the belt’s shape.

You can pull it with a little tension to account for belt stretch.

Steel tape is stiff and can’t hug the belt, so it gives you a less accurate measurement.

Flexible tools help you avoid errors and get the right belt length.

If you don’t have the old belt, use a nylon rope around the pulleys. Overlap the rope by a few inches, mark the spot, and measure the length. This gives you the measurement you need for ordering a new v-belt.

Q: What’s the most common mistake when measuring belts?

A: Many people use a steel tape or guess the length. This leads to wrong sizing and poor fit. Always use a flexible tape or string and measure the outside belt length.

When you finish measuring belts, write down the width, depth, and outside belt length. These numbers help you order the right v belt and keep your machine running smoothly.

Sometimes you need to measure a missing v-belt because the old one broke or disappeared. Don’t worry. You can still figure out the right size for your replacement. You just need to use the pulleys and a few simple tools.

When the belt is missing, you can use the pulleys to get the information you need. Start by looking at how many grooves each pulley has. This tells you if you need a single, double, or multi-groove belt. Next, you want to measure the center distance between the pulleys. This is the straight line from the center of one pulley to the center of the other. Getting this distance right is very important for the correct belt length.

Here’s a step-by-step way to measure using the pulleys:

Check the pulley setup. Is it single, double, or multi-groove?

Use a ruler or caliper to measure the diameter of each pulley at the groove where the belt sits.

Measure the center distance between the two pulleys. Place your ruler or tape measure from the center of one shaft to the center of the other.

Write down these numbers. You’ll use them to calculate the belt length.

Figure out the belt type and profile by looking at the pulley grooves and thinking about how much power your machine needs.

Tip: Use a caliper or a flexible tape to measure the groove diameter. This helps you get a more accurate measurement.

You can also use some handy tools for more precise results:

Calipers with a depth rod to measure from the pulley face to the groove.

Dividers to measure between groove bottoms, then check the span with a ruler.

Dowel pins or precision balls placed in the grooves to help find the exact center distance.

Once you have the pulley diameters and the center distance, you can calculate the belt length. Here’s a simple formula you can use:

Belt Length = (Pulley A Diameter × 1.57) + (Pulley B Diameter × 1.57) + (2 × Center Distance)

Add up these numbers and pick the closest standard belt length. This method helps you measure a missing v-belt with good accuracy.

If you don’t have the original belt, the string method is a great way to measure a missing v-belt. You only need a piece of string or rope and a ruler.

Follow these steps for the string method:

Choose a string or rope that fits snugly into the pulley grooves. This helps you follow the same path as the belt.

Tie a small loop at one end of the string. This makes it easier to pull the string tight.

Place the string in the groove of one pulley and wrap it around both pulleys, following the path the belt would take.

Keep the string tight as you go around. This simulates the tension of a real belt.

Mark the spot where the string meets or overlaps.

Remove the string and lay it flat on a table.

Measure the distance from the end of the string to your mark with a ruler or tape measure.

Note: For best results, use a flexible cloth tape measure instead of string if you have one. It wraps around the pulleys more easily and gives you a more accurate belt length.

Here’s a quick checklist to make sure you get it right:

Use a string that fits the grooves.

Keep the string tight, but don’t stretch it too much.

Mark the meeting point clearly.

Measure carefully with a ruler.

Sometimes, belts stretch a little over time. If you’re not sure, take your measurement to the parts store and try belts that are a little longer and a little shorter than your measured length. This helps you find the perfect fit.

Q: Is the string method accurate?

A: Yes, if you keep the string tight and follow the belt path closely, you can get a reliable measurement. Just remember, using a v-belt measuring tool or a cloth tape measure is even better if you have one.

When you measure a missing v-belt, you can use either the pulley measurement method or the string method. Both ways help you find the right belt length and keep your machine running smoothly.

You have measured your pulleys. Now you need to find the right belt length. First, write down the size of each pulley. Also, write the distance between the pulleys. These numbers help you pick the correct belt. If you measured your old belt, you can compare it to the sizes in charts. Sometimes, the belt has its size printed on it.

Here’s what you need:

Diameter of the bigger pulley (Dl)

Diameter of the smaller pulley (Ds)

Distance between the pulleys (L)

You can use these numbers with a formula. Or you can check the charts from the manufacturer. The charts show common belt sizes. They help you choose the best belt for your machine. The charts also explain how to match your measurement to the right belt type.

Tip: Always check your numbers again before you buy. Even a small mistake can mean you get the wrong belt.

You can use a formula to find the belt length. This formula works for most machines:

Variable / Parameter | Description |

|---|---|

Dl | Diameter of the bigger pulley |

Ds | Diameter of the smaller pulley |

L | Distance between the pulleys |

Here are two formulas you can use:

L = π(R + r) + 2a + (R - r)^2 / a L = π(R + r) + 2a + (R - r)^2 / (4a)

Where:

L is the belt length

R is the radius of the bigger pulley

r is the radius of the smaller pulley

a is the distance between pulleys

For a quick guess, try this formula:

V-Belt Length = (Pulley A Diameter × 1.57) + (Pulley B Diameter × 1.57) + (Center Distance × 2)

After you do the math, look at the chart for the closest size. The chart helps you match your number to a real belt. It also shows how to change your outside measurement to inside or pitch length. Always pick the closest standard size for the best fit.

Note: Manufacturer charts also give tips for setting the right tension. This helps your belt last longer and keeps your machine working well.

You want to make sure you order the correct V belt for your machine. Start by using your measurements to match the belt section and length. Classical V belts, like A, B, C, D, and E sections, use the inside circumference for their part numbers. If you measured the outside circumference, subtract a set amount based on the belt section. For example, subtract 2 inches for an A section, 3 inches for a B section, and so on. Combine this number with the section letter to get your part number. If you have a cogged belt, add an "X" after the section letter. For banded belts, add the number of bands and a slash before the section.

Here’s a quick guide to help you:

Measure the belt width and depth to find the section (like A, B, C).

Use a cloth tape or string to measure the outside circumference.

Subtract the section-specific value to get the inside circumference.

Write the part number as Section + Inside Circumference (e.g., B62).

For cogged belts, use BX62. For banded belts, use 3/B62.

Double-check your measurements to avoid mistakes.

Tip: Always measure under slight tension and check for belt stretch or wear. This helps you get the most accurate part number.

Sometimes you can’t find the exact part number or your belt is discontinued. Cross-referencing helps you find compatible V belts from different suppliers. You compare key details like dimensions, type, and performance. This makes it easier to replace a belt, even if the original is hard to find.

Here’s how you can cross-reference like a pro:

Match your measurements (width, depth, length) to standard belt charts.

Use online cross-reference tools or manufacturer guides.

Compare belt type and material for best performance.

Check for special designations, like cogged or banded.

Ask for technical support if you’re unsure about compatibility.

Always verify the belt’s specs before ordering.

Q: What if you need a custom or hard-to-find belt?

A: Reach out to a trusted manufacturer for help. At Uliflex, we specialize in industrial belts and timing belts. We offer free technical support and custom solutions for unique applications. You can send us your measurements or a sample, and we’ll design a matching belt for your machine.

Service Type | What You Get |

|---|---|

Free Technical Help | Expert advice for sizing and selection |

Custom Solutions | Made-to-order belts for special machines |

Fast Quotes | Quick response and shipment |

OEM/ODM Service | Belts with your logo and custom features |

If you need help with belt sizing, cross-referencing, or sourcing a special belt, just contact us. We make it easy to keep your machines running smoothly.

Note: Using accurate measurements and cross-referencing ensures you get the right V belt every time. This saves you time, money, and trouble.

Measuring and replacing a v belt might seem simple, but small mistakes can lead to big problems. You want your machine to run smoothly, so watch out for these common errors:

Using the wrong tools, like a steel tape or guessing belt tension by feel. Only a proper belt tension gauge gives you an accurate reading.

Loose or sloppy measurements. If you don’t pull the tape snug or mark the string carefully, you might end up with the wrong belt size.

Misreading the belt profile or section. Always double-check the width and depth before ordering.

Installing belts with twists or kinks, which can cause early failure.

Not replacing worn or damaged pulleys when you change the belt. Worn pulleys can cause rapid sidewall wear and slipping.

Failing to re-tension the belt after 24-48 hours of use. Belts stretch a bit after installation and need a quick adjustment.

Letting oil, grease, or dirt get on the belt. Contamination can make the belt slip or swell.

Ignoring pulley alignment. Misaligned pulleys lead to noise, vibration, and faster wear.

Not replacing all belts in a set at the same time. Mixing old and new belts causes uneven wear.

Tip: Always use a flexible cloth tape or a v belt measuring tool for the most accurate results. Avoid makeshift methods like the “thumb test” or visual guessing.

Sometimes, you might feel unsure about your measurements or the type of v belt your machine needs. Here’s when you should reach out for professional support:

You have a complex pulley system, like double v-belts or tension pulleys.

You can’t match your measurements to any standard belt size or profile.

You notice pulley wear, cracks, or damage that could affect belt fit.

You feel unsure about tensioning or alignment, or you lack the right tools.

You need to replace all belts in a set for even wear and performance.

You want to make sure your machine runs at peak efficiency and avoids downtime.

Note: Uliflex’s technical team can help you with accurate v belt sizing, custom solutions, and expert advice. If you ever feel stuck, don’t hesitate to ask for help. Getting it right the first time saves you time, money, and frustration.

Measuring a v belt the right way keeps your machine running smoothly. Here’s what you need to do:

Mark a clear starting point on the belt.

Use a cloth tape or v belt measuring tool—never a steel tape.

Measure the width, depth, and length twice for accuracy.

Double-check your numbers before you order.

Tip: If you get stuck, Uliflex’s free technical support can help you find the perfect belt.

You can find guides, how-to videos, and expert help online. Need a custom solution? Reach out using the contact options below:

Support Type | How to Connect |

|---|---|

Free Technical Help | Online form, phone, email |

Custom Belt Design | Send your specs or sample |

Ready to keep your equipment moving? Explore Uliflex’s resources or contact us for fast, friendly support!

You can use a string or cloth tape. Wrap it around the pulleys where the belt runs. Mark the spot where the ends meet. Measure the length with a ruler. This gives you the needed belt size.

A soft cloth tape or flexible measuring tape works best. You can also use a v belt measuring tool. Avoid steel tape measures because they don’t bend easily and can give you the wrong size.

Width and depth help you match the belt to your machine’s pulleys. If you use the wrong size, the belt may slip or wear out quickly. Always record these measurements before you order a new belt.

No, you need the correct type and size. Each machine uses a specific belt profile and length. Using the wrong belt can cause noise, poor performance, or damage. Always check your measurements and machine requirements.

You can contact Uliflex’s technical support team. They offer free advice and custom solutions. Send your measurements or a sample, and they’ll help you find the perfect belt for your machine.

The bell of 2026 has already rung, and the Uliflex team sends its best wishes to people from all countries. We pray for world peace and for people to live and work in contentment. In the new year, we hope everyone will continue to bravely be themselves and pursue their dreams.

The deviation of polyurethane industrial belts is indeed a common and tricky problem. Uliflex is here to help you sort out the core reasons and coping strategies. Based on Uliflex's years of experience in the polyurethane industrial belt industry, deviation is usually caused by uneven stress or mech

On October 28, 2025, the four-day 2025 China International Textile Machinery Exhibition and ITMA Asia Exhibition (Singapore) grandly kicked off at the Singapore Expo Center.

Polyurethane (PU) industrial belts are widely used in manufacturing, logistics, and automation due to their high strength, flexibility, and resistance to abrasion. However, their service life is often compromised by improper usage or environmental factors. To maximize longevity, operators must focus

In industrial automation equipment, PU (polyurethane) synchronous belts have become the preferred transmission components for precision industries such as 3C electronics and food processing due to their wear resistance, oil resistance, tear resistance, and other characteristics. However, PU material

This week, Uliflex's colleague handling customer relations received a request from a new customer who learned about Uliflex at the 2025 PTC Shanghai exhibition. The customer's factory has multiple packaging production lines and wants to replace a new batch of industrial belts for transmission for th

Uliflex will participate in the "2025 China International Textile Machinery Exhibition&ITMA Asia Exhibition" in Singapore from October 28th to 31st, 2025, which will be held at the Singapore Expo Centre. Uliflex's booth is located at B401 in Hall H3. We welcome customers, peers, experts and scholars

The timing belt is a crucial component of your vehicle's engine, ensuring that the crankshaft and camshaft operate in perfect synchronization. Over time, the timing belt can wear out, leading to potential engine damage if not replaced in a timely manner. Understanding the cost of timing belt replacement is essential for budgeting and maintaining your vehicle's performance. In this article, we will explore the average cost of timing belt replacement, factors that influence the cost, and when it is recommended to replace your timing belt

Professional Industry Belt Manufacturer